Capacitor start motors are a prevalent solution for single-phase applications, offering enhanced starting torque.

These motors utilize a capacitor in series with a starting winding to create a phase shift,

facilitating reliable startup, as detailed in various wiring diagrams and PDF guides.

Understanding the single phase motor wiring diagram with a capacitor start configuration is crucial

for proper installation and maintenance, ensuring optimal performance and longevity of the motor system.

Numerous resources, including manuals for Dayton motors and HOMA pumps, provide detailed wiring

instructions and schematics for these types of motors, often available as downloadable PDF documents.

What is a Capacitor Start Motor?

A capacitor start motor is a type of single-phase electric motor designed to produce a higher starting torque than other single-phase motor designs. This is achieved through the incorporation of a capacitor within the starting circuit. The capacitor creates a phase shift in the current supplied to the auxiliary, or starting, winding.

This phase shift generates a rotating magnetic field, enabling the motor to self-start under load. Once the motor reaches approximately 75% of its rated speed, a centrifugal switch disconnects the starting winding and capacitor from the circuit, allowing the motor to continue running on the main winding. Detailed single phase motor wiring diagrams, often found in PDF format, illustrate this process.

These motors are commonly used in applications requiring high starting torque, such as compressors, pumps, and conveyors. Understanding the capacitor start mechanism is key to interpreting the associated wiring diagrams and ensuring correct installation.

Why Use a Capacitor Start Motor?

Capacitor start motors are favored when applications demand significantly higher starting torque compared to standard split-phase motors. This makes them ideal for powering equipment like air compressors, refrigerators, and various pumps where initial load is substantial. Examining a single phase motor wiring diagram with a capacitor start reveals the mechanism behind this enhanced performance.

The inclusion of a capacitor in the starting circuit provides a substantial boost in starting torque, often three to four times greater than that of a resistance-start motor. Accessing a PDF detailing the wiring allows for safe and effective implementation.

Furthermore, these motors offer a relatively simple and cost-effective solution for applications requiring intermittent, high-torque starts. Proper wiring, as shown in available diagrams, ensures reliable operation and extends the motor’s lifespan.

Understanding the Wiring Diagram

Wiring diagrams, often found as PDFs, illustrate connections for capacitor start motors, detailing line voltage, start and run windings, and capacitor placement.

Careful study of these schematics is vital for correct installation and troubleshooting, ensuring safe and efficient motor operation.

Key Components in the Diagram

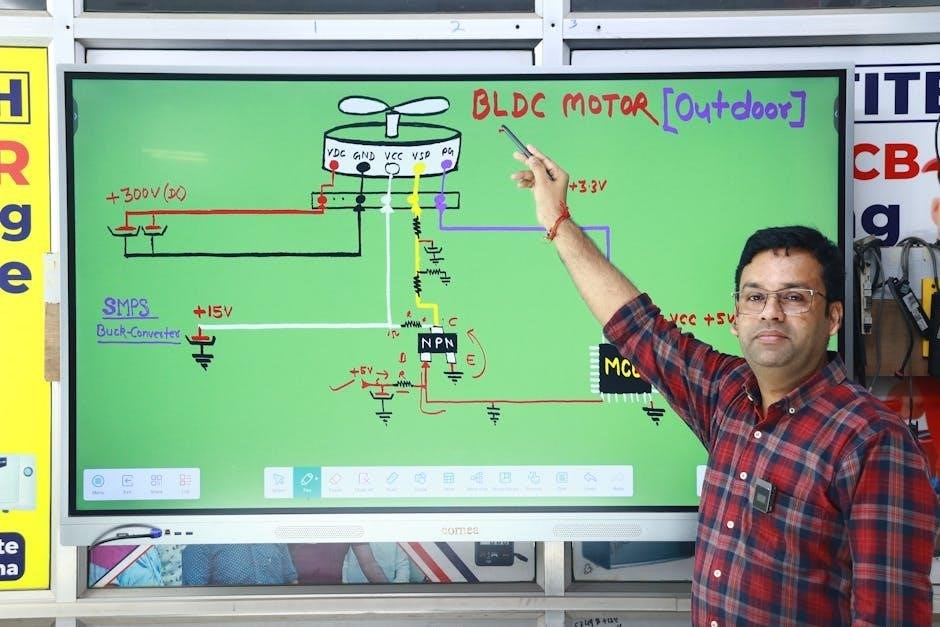

Single phase motor wiring diagrams with capacitor start configurations showcase several essential components. The diagram clearly identifies the line voltage inputs (L1 and L2), representing the power source feeding the motor. Crucially, it depicts the start winding, responsible for generating initial torque, and the run winding, sustaining rotation once started.

The start capacitor, a key element, is shown in series with the start winding, creating the necessary phase shift for starting. A run capacitor may also be present, improving efficiency and power factor during operation. Motor terminals, often labeled with letters or numbers, are clearly indicated, facilitating correct wire connections.

These diagrams, frequently available as PDF documents, also illustrate any included switches, like a change-over switch for reversing rotation. Understanding each component’s role and its placement within the wiring layout is paramount for successful installation and troubleshooting, as detailed in resources like Dayton motor manuals.

Identifying Motor Terminals

Accurately identifying motor terminals is vital when referencing a single phase motor wiring diagram with a capacitor start. Terminals are typically labeled, though conventions vary; common markings include ‘C’ for common, ‘S’ for start winding, ‘R’ for run winding, and numerical designations. PDF guides often include a terminal map specific to the motor model.

The ‘C’ terminal usually serves as the common connection point for both windings. The start winding terminal connects to the start capacitor, while the run winding connects directly to the power supply. Some diagrams use color-coding – blue or grey often indicate neutral connections.

Incorrect terminal connections can lead to motor failure or damage. Always cross-reference the diagram with the physical markings on the motor itself; Resources like Dayton manuals and HOMA pump documentation provide detailed terminal identification information for their respective motors.

Understanding Capacitor Values

When interpreting a single phase motor wiring diagram with a capacitor start configuration, grasping capacitor values is crucial. Capacitance, measured in microfarads (µF), dictates the phase shift created for starting torque. PDF guides will specify the correct µF rating for both the start and run capacitors.

The start capacitor, typically larger, provides a significant phase shift for initial rotation, then disconnects via a centrifugal switch. The run capacitor, smaller in value, remains in the circuit to improve running efficiency and power factor. Using incorrect values can severely impact performance.

Dayton and HOMA documentation emphasize using capacitors with appropriate voltage ratings. Always match the specified µF and voltage from the wiring diagram; substituting values can lead to motor damage or failure. Proper capacitor selection ensures optimal motor operation.

Capacitor Start Motor Wiring – Basic Setup

Capacitor start motor wiring, detailed in single phase motor wiring diagram PDF guides, involves connecting the start and run capacitors to the appropriate windings.

Correct wiring ensures proper phase shifting for starting and efficient operation, as illustrated in various diagrams for both single and dual voltage motors.

Wiring for Single Voltage Motors

Wiring a single voltage capacitor start motor, as depicted in a typical single phase motor wiring diagram PDF, is a relatively straightforward process. The primary power supply connects to the main winding terminals, usually labeled ‘L1’ and ‘L2’ or ‘Line’ and ‘Neutral’. The start winding, crucial for initial torque, receives power through the start capacitor.

This capacitor is connected in series with a centrifugal switch, which automatically disconnects the start winding once the motor reaches approximately 75% of its rated speed. The run capacitor, essential for continuous operation and improved efficiency, remains connected to the auxiliary winding.

Carefully consult the motor’s specific wiring diagram, often found within the PDF documentation, to identify the correct terminal connections. Incorrect wiring can lead to motor failure or safety hazards. Always ensure proper grounding and secure connections for reliable performance.

Wiring for Dual Voltage Motors

Dual voltage capacitor start motors offer flexibility, operating on different voltage supplies. A single phase motor wiring diagram PDF for these motors will illustrate a T-connection for the main winding. This allows selecting either a higher or lower voltage configuration by connecting the supply to different tap points on the winding.

The start winding and start capacitor function similarly to single voltage setups, providing initial torque. The centrifugal switch remains vital for disconnecting the start winding after reaching operational speed. The run capacitor continues to enhance efficiency.

Always verify the motor’s voltage rating and select the appropriate tap on the main winding before connecting the power supply. Refer to the specific wiring diagram within the motor’s PDF manual to ensure correct connections and avoid damage;

Connecting the Run Capacitor

The run capacitor, a crucial component in a capacitor start motor, remains in the circuit during both starting and running phases. A detailed single phase motor wiring diagram PDF will show it connected in series with the auxiliary winding. This continuous phase shift improves the motor’s running efficiency and power factor.

Unlike the start capacitor, which is disconnected by a centrifugal switch, the run capacitor is permanently connected. Selecting the correct capacitance value, as specified in the motor’s documentation or wiring diagram, is vital for optimal performance.

Incorrect capacitance can lead to overheating or reduced torque. Always ensure the run capacitor is properly rated for the voltage and current of the motor, and consult the PDF manual for specific connection instructions.

Detailed Wiring Diagrams

Detailed wiring diagrams, often found in PDF format, illustrate connections for capacitor start motors, including Diagram DD1 and DD2,

showing capacitor placement and winding configurations.

Dayton motor wiring diagrams provide specific schematics, while resources detail single phase motor wiring for various applications.

Diagram DD1 – Standard Capacitor Start Wiring

Diagram DD1 represents a commonly utilized standard capacitor start wiring configuration for single phase motors. This schematic, frequently available as a PDF, details the connection of the main power supply (L1 & L2) to both the start and run windings. Crucially, the start winding is connected in series with a start capacitor, which is essential for generating the necessary phase shift to initiate rotation.

The diagram clearly illustrates how the capacitor is only engaged during the starting phase, typically disconnected via a centrifugal switch once the motor reaches approximately 75% of its rated speed. The run winding remains continuously energized, providing the sustained torque for ongoing operation. Understanding the precise placement of the capacitor and the centrifugal switch is vital for correct wiring.

PDF versions of Diagram DD1 often include notes regarding appropriate capacitor values based on motor horsepower and voltage, ensuring optimal starting performance. Careful adherence to this wiring layout is paramount for safe and efficient motor operation.

Diagram DD2 – Alternative Capacitor Start Wiring

Diagram DD2 presents an alternative capacitor start wiring method for single phase motors, often found within comprehensive PDF guides detailing motor connections. While functionally similar to Diagram DD1, it differs in the specific arrangement of the start winding, run winding, and the start capacitor within the circuit. This variation can sometimes offer advantages in specific applications or motor designs.

Like the standard configuration, Diagram DD2 emphasizes the importance of a centrifugal switch to disconnect the start capacitor once the motor reaches operating speed. The PDF documentation accompanying this diagram typically highlights the correct capacitor specifications and wiring sequence.

This alternative approach may be preferred based on available components or to optimize starting characteristics. Always consult the motor’s specific wiring diagram and adhere to safety guidelines when implementing this configuration.

Dayton Capacitor Start Motor Wiring Diagram

Dayton Capacitor Start Motor Wiring Diagrams are readily available, often as downloadable PDF documents, providing detailed instructions for connecting these commonly used single phase motors. These diagrams typically illustrate both standard and alternative wiring configurations, catering to various motor models and voltage requirements;

The Dayton documentation emphasizes the correct identification of motor terminals – Run, Start, Common, and Line – alongside the proper selection and connection of the start capacitor and run capacitor. The PDF guides also clearly depict the role of the centrifugal switch in disconnecting the start capacitor after startup.

Users should carefully review the specific diagram corresponding to their Dayton motor model to ensure accurate wiring and safe operation. These resources are invaluable for both installation and troubleshooting.

Changing Motor Rotation Direction

Reversing rotation in capacitor start motors requires swapping the connections to either the start or run winding, often utilizing a change-over switch.

Wiring diagrams, found in PDF guides, illustrate how to achieve this, ensuring correct phase relationships for the desired rotational direction.

Using a Change-Over Switch

Change-over switches are essential components when needing to reverse the rotation of a capacitor start motor. These switches effectively interchange the connections to the start winding, altering the phase relationship and thus, the direction of the rotating magnetic field.

A typical single phase motor wiring diagram with a capacitor start configuration, often available as a PDF, will demonstrate how the switch is integrated. The switch doesn’t typically affect the run winding or the run capacitor, only the start winding and its associated connections.

When utilizing a change-over switch, it’s crucial to ensure all power is disconnected before making any wiring adjustments; Incorrect wiring can lead to motor damage or safety hazards. Refer to the motor’s specific wiring diagram, often found in the product manual or online as a PDF, for accurate connection points and switch configuration. Always double-check the connections before restoring power.

Wiring for Reverse Rotation

Achieving reverse rotation in a capacitor start motor requires altering the phase shift created by the start winding. A detailed single phase motor wiring diagram, frequently available as a PDF, illustrates the necessary modifications. Typically, this involves swapping the connections to the start winding – effectively reversing its polarity.

The run winding and run capacitor connections remain unchanged during a rotation reversal. However, carefully examine the wiring diagram for your specific motor model, as variations exist. Incorrect wiring can damage the motor or prevent it from starting.

Always disconnect power before attempting to reverse the rotation. Consult the PDF documentation for your motor, paying close attention to terminal designations. Proper implementation, guided by the diagram, ensures safe and reliable operation in the desired direction.

Types of Single Phase Motors & Capacitors

Single phase motors include Permanent Split Capacitor (PSC), and Capacitor Start Capacitor Run types, each utilizing different capacitor configurations.

Wiring diagrams, often in PDF format, detail the specific capacitor connections for start and run functions, impacting motor performance.

Permanent Split Capacitor (PSC) Motors

Permanent Split Capacitor (PSC) motors represent a simplified single-phase motor design, differing significantly from capacitor start configurations. Unlike motors requiring a dedicated start capacitor, PSC motors utilize a single capacitor continuously connected in series with the auxiliary winding.

This constant phase shift provides moderate starting torque, making them suitable for applications like fans and blowers where high starting power isn’t critical. Examining a single phase motor wiring diagram for PSC motors reveals a straightforward setup, often detailed in PDF guides.

These diagrams typically illustrate the direct connection of the capacitor to both the auxiliary winding and the main power supply. While simpler than capacitor start motors, understanding the wiring is still essential for correct installation and troubleshooting. Resources like motor manuals and online schematics provide comprehensive wiring information.

Capacitor Start Capacitor Run Motors

Capacitor Start Capacitor Run motors combine the benefits of both capacitor start and PSC designs, offering high starting torque alongside efficient running performance; These motors employ two capacitors: a larger start capacitor for initial torque and a smaller run capacitor for continuous operation, as illustrated in a detailed single phase motor wiring diagram.

A PDF guide showcasing the wiring will reveal a more complex configuration than PSC motors, with separate connections for each capacitor. The start capacitor is typically disconnected once the motor reaches a certain speed, often via a centrifugal switch.

This design provides superior starting capabilities while maintaining good efficiency during normal operation. Understanding the specific wiring layout, including capacitor values and switch functionality, is crucial for proper installation and maintenance, as detailed in manufacturer’s documentation.

Run Capacitor vs. Start Capacitor

The distinction between a run capacitor and a start capacitor is fundamental to understanding capacitor start motor operation, and is clearly depicted in a single phase motor wiring diagram. A start capacitor, typically larger, provides a high initial torque for starting, but is designed for intermittent duty.

Conversely, the run capacitor, smaller in value, remains in the circuit continuously during operation, improving efficiency and power factor. A PDF guide will illustrate how the start capacitor is switched out of the circuit via a centrifugal switch or relay.

Using the incorrect capacitor can lead to motor failure or reduced performance. The wiring diagram emphasizes the correct placement and specifications for each capacitor, ensuring optimal motor function and longevity.

Troubleshooting Common Wiring Issues

Wiring diagrams, often found as PDFs, aid in diagnosing issues like a motor failing to start or running slowly.

Checking capacitor functionality and connections is vital for resolving these problems.

Motor Not Starting

Diagnosing a motor that won’t start requires a systematic approach, often aided by a clear single phase motor wiring diagram, readily available in PDF format. First, verify power supply to the motor, ensuring correct voltage and a functioning circuit breaker. Next, meticulously inspect all wiring connections, referencing the diagram to confirm proper placement of wires to the start and run windings, and the capacitor itself.

A common culprit is a faulty start capacitor; test it with a capacitance meter. If the capacitor is open or significantly out of specification, replace it. Also, check the centrifugal switch – it should engage when the motor reaches approximately 75% of its rated speed, disconnecting the start winding. A failed switch prevents proper operation. Finally, examine the start winding for open circuits using a multimeter. Detailed wiring diagrams in PDF guides often highlight these components for easy identification.

Motor Runs Slowly

If a capacitor start motor operates at a reduced speed, several issues could be present, and a single phase motor wiring diagram in PDF format is invaluable for troubleshooting. A weakening run capacitor is a frequent cause; its diminished capacitance reduces the motor’s ability to maintain optimal speed. Test the capacitor with a meter and replace if necessary.

Inspect the wiring connections, ensuring they are tight and free from corrosion, as loose connections increase resistance and hinder performance. Verify the voltage supply is within the motor’s specified range. A partially failed start winding can also contribute to slow operation. Referencing a detailed wiring diagram will help pinpoint the winding’s terminals for testing. Finally, check for mechanical loads exceeding the motor’s capacity, as this can strain the motor and reduce its speed.

Capacitor Failure Symptoms

Identifying capacitor failure in a capacitor start motor is crucial, and a single phase motor wiring diagram (often found as a PDF) aids diagnosis. Common symptoms include the motor humming but failing to start, or starting only with manual assistance. A bulging or leaking capacitor is a visual indicator of failure.

The motor may run slowly, exhibit reduced torque, or overheat. Frequent tripping of the overload protector suggests a capacitor issue. Using a multimeter to test the capacitor’s capacitance is essential; a significant deviation from its rated value confirms failure. Always discharge the capacitor before handling it, as it stores a potentially dangerous electrical charge. Consult the wiring diagram to correctly identify the start and run capacitors.

Safety Precautions

Always disconnect power before working with wiring. Capacitors store energy – discharge them safely before handling, referencing a PDF diagram.

Prioritize electrical safety!

Working with Electricity

Electrical work involving a single phase motor wiring diagram with a capacitor start configuration demands utmost caution. Always disconnect the power supply at the circuit breaker or fuse box before commencing any wiring or inspection. Confirm the power is off using a reliable voltage tester. Never assume a wire is de-energized; verify it.

When referencing a PDF guide or diagram, understand that these are visual aids and do not replace safe work practices. Use insulated tools specifically designed for electrical work. Avoid working in damp or wet conditions, as water significantly increases the risk of electric shock. If you are unfamiliar with electrical wiring, consult a qualified electrician. Incorrect wiring can lead to fire hazards, motor damage, or personal injury.

Double-check all connections before restoring power, ensuring they are secure and properly insulated. Remember, safety is paramount when dealing with electricity.

Capacitor Discharge

Capacitors, integral to a single phase motor wiring diagram with a capacitor start setup, store electrical energy even after the power is disconnected. This retained charge can deliver a dangerous shock. Always discharge the capacitor before handling any wiring, even after disconnecting power.

A safe method involves using an insulated screwdriver with a resistor (typically 10,000 to 20,000 ohms, 5 watts) across the capacitor terminals. Shorting the terminals briefly dissipates the stored energy. Refer to your PDF guide for specific capacitor discharge instructions. Never touch the capacitor terminals with bare hands.

Proper capacitor discharge is a critical safety step, preventing accidental shock during maintenance or troubleshooting. Ignoring this precaution can result in serious injury. Verify discharge with a multimeter before proceeding with any work.

Resources and Further Information

Explore HOMA pump capacitor wiring guides and 1EMPC/1EMPCC motor documentation for detailed diagrams. Downloadable PDFs offer specific single phase motor wiring solutions.

HOMA Pump Capacitor Wiring

HOMA single-phase TP, A, and GRP series pumps commonly utilize externally wired capacitors, a crucial aspect of their operation detailed in available single phase motor wiring diagrams. Many HOMA pumps are supplied with a single run capacitor only, omitting a dedicated start capacitor, simplifying the wiring process.

However, understanding the specific capacitor requirements for your HOMA pump model is paramount. Refer to the pump’s documentation or a dedicated wiring diagram, often available as a PDF download from the manufacturer’s website, to identify the correct capacitor value and wiring configuration. These diagrams clearly illustrate the connections between the power supply, the motor windings, and the capacitor, ensuring proper functionality and preventing damage.

Always prioritize safety when working with electrical components, and consult a qualified electrician if you are unsure about any aspect of the wiring process. Proper capacitor wiring is essential for the reliable and efficient operation of your HOMA pump.

1EMPC & 1EMPCC Motor Wiring

1EMPC designates Permanent Capacitor Motors, while 1EMPCC signifies Capacitor Start Capacitor Run Motors. Both types require careful attention to wiring, often detailed in a single phase motor wiring diagram available as a PDF. When a change in rotation direction is needed for either motor type, a change-over switch is typically employed.

The wiring diagrams for these motors illustrate how to connect the start and run capacitors, along with the motor windings, to achieve the desired functionality. PDF guides often showcase specific configurations for single and dual voltage applications. Understanding the difference between start and run capacitors is vital for correct wiring.

Always consult the motor’s specific wiring diagram before commencing any electrical work, and prioritize safety by disconnecting power before making any connections.

Finding Motor Specific Diagrams

Locating the precise single phase motor wiring diagram, often in PDF format, is crucial for successful installation and troubleshooting of capacitor start motors. Manufacturer websites are excellent starting points; search using the motor’s model number. Many distributors also provide downloadable wiring diagrams for the motors they sell;

Online forums dedicated to electrical engineering and motor repair frequently host collections of PDF schematics. Searching for “capacitor start motor wiring diagram” along with the motor’s brand and model number will yield targeted results. Resources like those for Dayton and HOMA motors are particularly helpful.

Remember to verify the diagram matches your specific motor’s voltage and horsepower rating before proceeding with any wiring.

Comments